PPR Tee: The Versatile Connector for Piping Networks

Introduction

The PPR Tee, a crucial component in polypropylene random copolymer (PPR) piping systems, offers unparalleled versatility and functionality. Its unique design allows for the efficient branching of pipework, making it a staple in both residential and industrial plumbing applications. This article delves into the intricacies of the PPR Tee, exploring its features, applications, and significance in modern piping networks.

Design and Construction

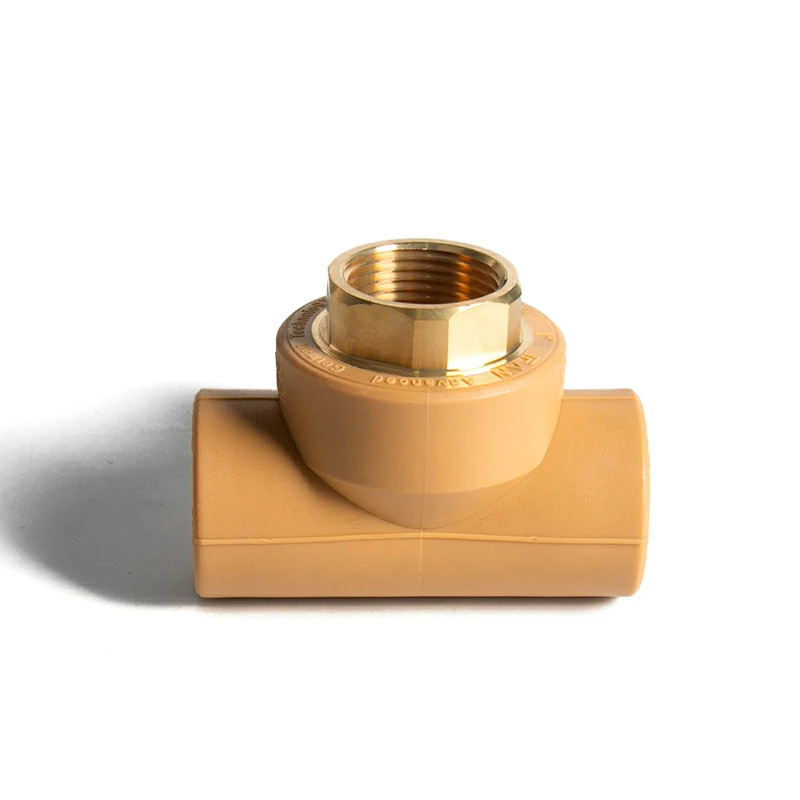

The PPR Tee boasts a sturdy yet lightweight construction, thanks to its polypropylene random copolymer composition. This material’s inherent strength, flexibility, and corrosion resistance ensure that the Tee can withstand a wide range of operating conditions, including high pressures, temperatures, and chemical exposures. Its design features three openings: two in-line ports for the main flow path and a lateral port for branching, all precision-molded to ensure a seamless connection with other PPR pipes and fittings.

Functionality and Benefits

The primary function of the PPR Tee is to facilitate the branching of piping systems without compromising the flow efficiency or structural integrity of the network. Its ability to smoothly direct fluid flow from the main line to a secondary branch line simplifies plumbing designs and enhances system flexibility. Furthermore, the use of PPR material eliminates the need for galvanic corrosion-prone metals, reducing maintenance costs and extending system lifespan.

Installation and Compatibility

Installing a PPR Tee is a straightforward process that requires minimal tools and expertise. It can be easily fused, threaded, or otherwise connected to PPR pipes and fittings, ensuring a strong, leak-proof joint. Its compatibility with a wide range of PPR pipe sizes and pressure ratings makes it suitable for use in diverse applications, from small residential plumbing systems to large-scale industrial fluid handling networks.

Applications in Plumbing and Industry

The PPR Tee finds widespread use in various plumbing and industrial settings. In residential applications, it is commonly employed for distributing water throughout homes, connecting showerheads, faucets, and other fixtures to the main water supply line. In industrial settings, it plays a crucial role in fluid handling systems, facilitating the transfer of chemicals, gases, or water between different processes or equipment. Its versatility and durability make it an invaluable asset for engineers and plumbers alike.

Maintenance and Durability

Proper maintenance and inspection of PPR Tees are essential to ensuring the continued performance and longevity of piping systems. Regular checks for leaks, cracks, or signs of wear should be conducted, with prompt replacement of damaged components. The inherent durability of PPR material, however, significantly reduces the likelihood of such issues, ensuring a reliable and long-lasting connection.

Advantages Over Traditional Materials

Compared to traditional piping materials such as copper or galvanized steel, PPR Tees offer several advantages. Firstly, PPR’s lightweight nature simplifies transportation, handling, and installation, reducing labor costs and installation time. Secondly, its corrosion resistance eliminates the risk of leaks caused by rust or galvanic corrosion, enhancing system safety and reliability. Lastly, PPR’s flexibility allows for easier routing and installation in tight spaces, making it an ideal choice for complex piping designs.

Future Developments and Trends

As technology continues to evolve, PPR Tees and the entire PPR piping industry are poised for further advancements. Innovations in material science may lead to even stronger, more durable PPR formulations, while advancements in manufacturing techniques could result in more precise, cost-effective production processes. Additionally, the increasing adoption of smart, connected plumbing systems may necessitate the development of sensor-integrated PPR Tees that can monitor flow rates, pressures, and other parameters in real-time, enhancing system efficiency and reliability.

Conclusion

In conclusion, the PPR Tee is a versatile and essential connector for modern piping networks. Its sturdy construction, functionality, and compatibility with a wide range of applications make it a preferred choice for engineers, plumbers, and other professionals working in the plumbing and fluid handling industries. As the industry continues to progress, we can expect to see even more innovative developments in PPR Tee technology, further enhancing the safety, reliability, and efficiency of piping systems worldwide.

| Best PPR PRODUCTS Manufacturers | ||

| Companies | Headquarter/Location | Year Founded |

| it | ZHEJIANG,CHINA | 1993 |

| RAKtherm | UAE | 1963 |

| REHAU | Muri bei Bern, Switzerland | 1948 |

| POLOPLAST | Leonding, Austria | 1954 |

| ERA | ZHEJIANG,CHINA | 1983 |

| LESSO | GUANGDONG,CHINA | 1986 |

Products international standards

products strictly adhere to a comprehensive range of international standards, encompassing ISO 15874, EN 15874, ASTM F2389, DIN 8077/8078, GB/T 18742, NBR 15884, ISO 15494, EN ISO 15494, GB/T 19472, NBR 15494, ASTM 2846 (501), DIN 8079/8080 (502), ASTM F441/F441M SCH80 (503), DIN (504), DIN (505), GB/T 18993, AS/NZS 1477, CSA B137.6, NSF/ANSI 14, TIS 17-2532/1131-2535, BS 3505, BS 4346 (801), ASTM D1785 SCH40 (802), ASTM D1785 SCH80 (803), DIN (804), GB (805), GB (806), GB(901), DWV(902), ASTM D2665 (903), along with ASTM D2241, D2665, D2729, and F441/F441M series, ISO 1452, EN ISO 1452, DIN 8061/8062, GB/T 10002, AS/NZS 1477, JIS K6741, CSA B137.3, and other national and industry norms.