HDPE pipes have become a staple in various industries. Their high – density polyethylene material offers unique advantages. First, HDPE pipes are highly durable. They can withstand harsh environmental conditions, such as extreme temperatures and high – pressure situations. This durability makes them ideal for long – term applications.

Another key benefit is their corrosion resistance. Unlike metal pipes, HDPE pipes do not rust or corrode. This property extends their lifespan and reduces maintenance costs. In water supply systems, for example, HDPE pipes ensure clean and safe water transportation without the risk of contaminants from pipe corrosion.

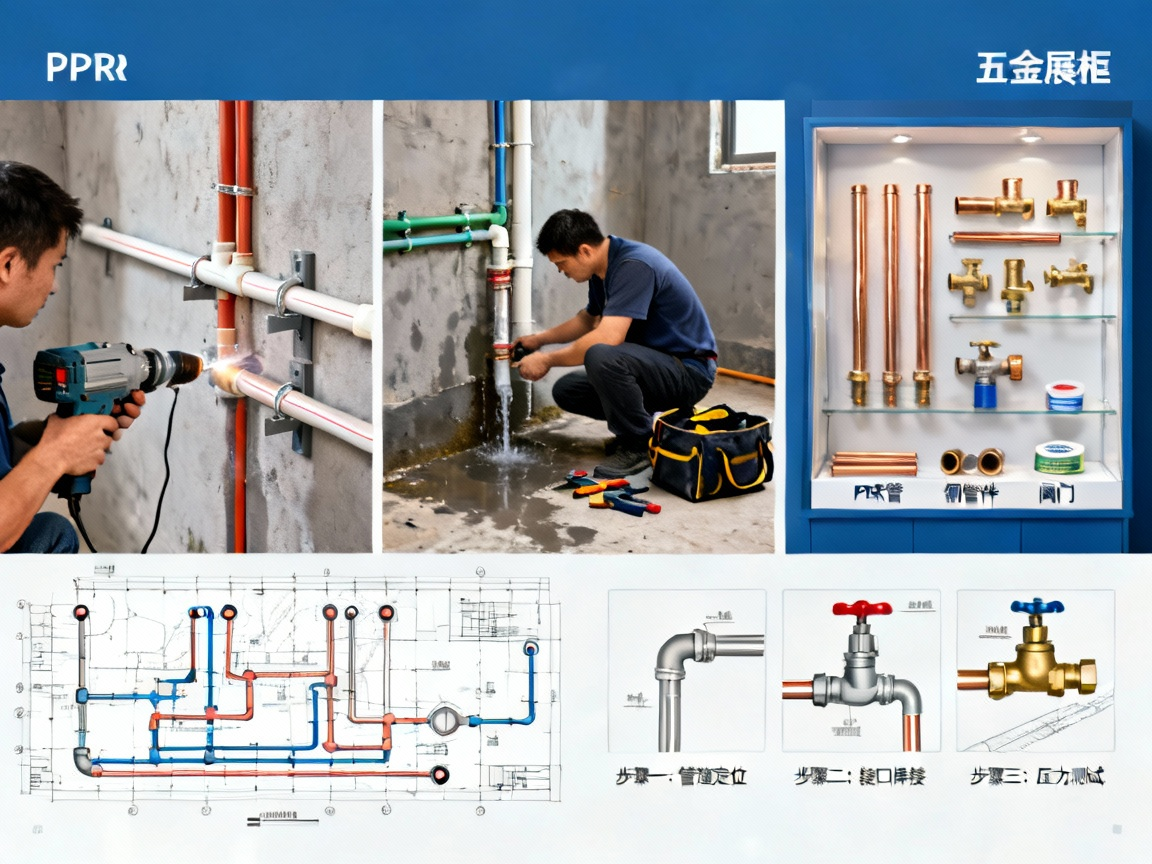

Installation of HDPE Pipe

Installing HDPE pipes is relatively straightforward. They are lightweight, which makes handling and transportation easier. Their flexibility allows for easy bending during installation, reducing the need for numerous fittings. This not only speeds up the installation process but also minimizes potential leak points.

Moreover, HDPE pipes can be joined using different methods. Fusion welding is a popular choice, which creates a strong and seamless joint. This joint is as strong as the pipe itself, ensuring a reliable connection for fluid or gas transportation.

Applications of HDPE Pipe

HDPE pipes find wide applications in the water industry. They are used for both potable water supply and wastewater management. Their smooth inner surface reduces friction, enabling efficient water flow. This results in lower energy consumption for pumping water.

In the gas industry, HDPE pipes are also widely used. They can safely transport natural gas due to their excellent gas – tightness and resistance to chemical substances in the gas. This ensures the safety of gas distribution systems.

Additionally, HDPE pipes are used in agricultural irrigation. They can be laid underground or above – ground, providing a reliable water supply to crops. Their durability allows them to withstand the rigors of agricultural environments.

Environmental Impact

HDPE pipes are environmentally friendly. They are made from recyclable materials, which reduces the demand for new raw materials. At the end of their lifespan, they can be recycled into new products, minimizing waste.

Furthermore, their energy – efficient nature during operation helps in reducing overall energy consumption. This contributes to a more sustainable future, making HDPE pipes a great choice for environmentally – conscious projects.

In conclusion, HDPE pipes offer a combination of durability, corrosion resistance, easy installation, and wide applications. Their environmental friendliness further enhances their appeal. As technology advances, we can expect even more innovative uses of HDPE pipes in the future.