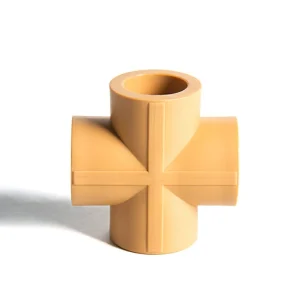

Introduction to PPR Socket

PPR (Polypropylene Random Copolymer) socket are essential components in modern plumbing systems. They ensure a secure and leak-proof connection between PPR pipes. This article provides an in-depth look at the features, benefits, and applications of PPR inner pressure sockets.

Features of PPR Sockets

PPR sockets possess several key features. These include high durability, resistance to chemicals, and ease of installation.

High Durability

PPR sockets offer high durability. They withstand extreme temperatures and pressures without compromising their structural integrity. This makes them suitable for various plumbing applications.

Resistance to Chemicals

PPR sockets resist a wide range of chemicals. This property makes them ideal for transporting chemicals and other corrosive substances. They do not degrade or corrode over time.

Ease of Installation

PPR sockets are easy to install. They require simple tools and techniques, such as heat fusion welding. This ensures a quick and efficient installation process.

Benefits of Using PPR Sockets

Using PPR sockets in plumbing systems offers numerous benefits. These include cost-effectiveness, reliability, and environmental friendliness.

Cost-Effectiveness

PPR inner pressure sockets provide a cost-effective solution for plumbing systems. Their affordability, combined with low installation and maintenance costs, makes them an economical choice.

Reliability

PPR sockets ensure reliable connections between pipes. They prevent leaks and breaks, providing consistent performance over time. This enhances the overall reliability of the plumbing system.

Environmental Friendliness

PPR sockets are environmentally friendly. They are made from recyclable materials and do not release harmful substances. Their energy-efficient production process reduces their carbon footprint.

Applications of PPR Inner Pressure Sockets

PPR sockets are versatile and can be used in various applications. These include residential plumbing, commercial plumbing, and industrial piping systems.

Residential Plumbing

In residential plumbing, PPR sockets connect pipes in water supply and heating systems. They ensure a reliable and leak-free connection, providing a steady flow of water to different parts of the home.

Commercial Plumbing

Commercial plumbing systems benefit from PPR sockets due to their durability and reliability. They are used in office buildings, hotels, and shopping centers to distribute water efficiently and safely.

Industrial Piping Systems

PPR sockets are suitable for industrial piping systems. Their chemical resistance makes them ideal for transporting chemicals, oils, and other industrial fluids. They ensure a secure and leak-proof connection, preventing contamination and loss of fluids.

Installation Process of PPR Inner Pressure Sockets

Proper installation of PPR sockets is crucial for their optimal performance. The process involves cutting, cleaning, and joining the pipes and fittings using heat fusion welding.

Cutting and Cleaning

First, cut the pipes to the required length using a pipe cutter. Clean the ends of the pipes and the inside of the coupling to remove any dirt or debris. This ensures a clean and secure joint.

Heat Fusion Welding

Heat fusion welding is the preferred method for joining PPR sockets. the ends of the pipes and the inside of the coupling using a welding tool. Once the plastic becomes soft, quickly join the pipes and coupling together. Hold them in place until they cool and form a strong, leak-proof joint.

Maintenance of PPR Inner Pressure Sockets

Regular maintenance ensures the longevity and performance of PPR sockets. Periodic inspections and cleaning help identify and address potential issues before they become serious problems.

Periodic Inspections

Inspect the PPR sockets periodically for signs of wear, leaks, or damage. Check for any loose joints or fittings and tighten them if necessary. Replace any damaged components to maintain the integrity of the plumbing system.

Cleaning

Clean the PPR sockets regularly to prevent the buildup of dirt and debris. This ensures smooth water flow and prevents blockages. Use mild cleaning agents and avoid harsh chemicals that can damage the fittings.

Environmental Considerations

PPR sockets support environmental sustainability. They are made from recyclable materials, reducing environmental impact. Their energy-efficient production and long lifespan contribute to overall environmental benefits.

Recycling

PPR sockets are 100% recyclable. At the end of their service life, they can be processed into new products, reducing waste and conserving resources. Proper disposal and recycling practices minimize environmental impact.

Conclusion

PPR sockets are essential components in modern plumbing systems. Their features, benefits, and versatility make them a preferred choice for various applications. Understanding their characteristics and applications aids in effective management of plumbing installations. By utilizing high-quality PPR inner pressure sockets, users can enhance the reliability, efficiency, and sustainability of their plumbing systems. Their durability, ease of installation, and environmental benefits make them an excellent choice for residential, commercial, and industrial applications.